It requires time, effort, and money to spread the culture of smart and sustainable asset management in any. But the benefits it will bring will exceed the effort many times over. The more widely the equipment management processes and tools are in use, the more financial benefits you will achieve.

So, let's go over what kind of financial savings and return on investment (ROI) you can expect from sustainable equipment management culture - AssetOps - and the Trail Equipment Management system.

As an example in calculating the ROI of equipment management, we use two companies of different sizes. The calculations are based on our customer surveys.

Do you want to hear the ROI of equipment management in your company? Contact us!

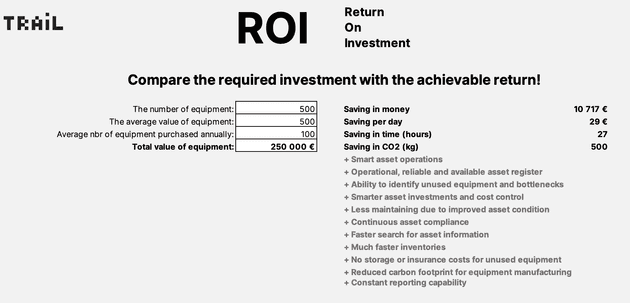

Equipment management ROI for an SME

Company A is an SME tracking 500 assets with Trail Equipment Management system. The average price of the company's assets is €500, and, on average, it acquires 100 new assets each year.

The picture above shows the savings that the company can achieve. Each year, AssetOps brings more than €10,000 in savings and reduces 27 hours of unnecessary work.

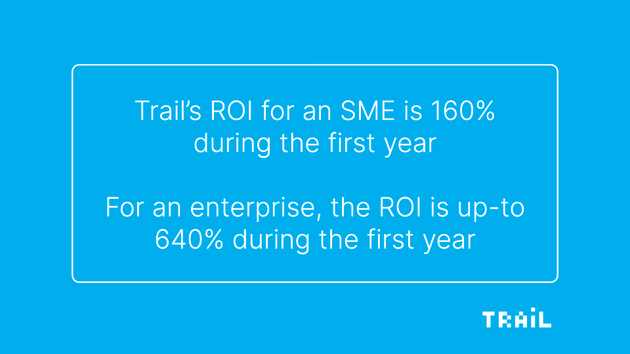

If you take Trail Equipment Management’s pricing into account, the return on investment is over 160% in the the first year and even greater after that.

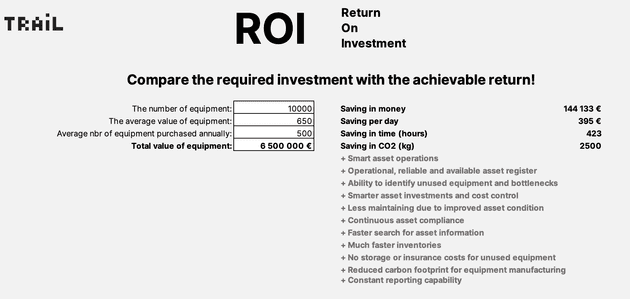

Equipment management ROI for an enterprise

Company B is a large company with 10,000 assets to track. The average price of the assets is €650. It acquires an average of 500 new assets annually.

The accumulated savings increase as the number of tracked assets grow. Every year, company B saves over €144,000 in costs and over 420 hours in work time.

Trail’s monthly price is determined dynamically according to the number of tracked assets. The more assets there are in the system, the lower the monthly fee per article.

Thanks to the pricing model, Trail's ROI for Company B is staggering 640% in the first year.

Reduction in environmental impact

Sustainable companies focus on the environmental effects of all of their operations. So far, the company's movable assets have long been an underutilised opportunity for reducing organisations’ environmental impact.

The attitudes are changing, though. Companies are being increasingly responsible in their purchase processes and they more attention to the life cycle of their existing equipment.

AssetOps helps companies to extend the life cycle of their movable assets, recycle equipment, and reduce unnecessary purchases. As a result, it helps organisations to introduce a new method for reducing the company's carbon footprint.

Therefore, the above ROI calculations also include the reduction of the carbon. In the example of company A, AssetOps saves annually approximately 500 kg of additional CO2 emissions (the same as a round-trip flight for one person from Helsinki to Malaga). In the example of company B, the annual CO2 saving is 2500 kg.

The calculation of CO2 emission reduction is based on the average emissions caused by the manufacturing of the assets.

How does AssetOps create savings and other benefits?

We have investigated the sources of savings and other benefits that smart equipment management brings. According to these studies, we have identified the following 11 ways AssetOps brings benefits to companies:

- Control over the equipment improves decision-making

- A functional, reliable and accessible device register reduces the time spent searching for information

- The ability to identify unused equipment allows to maximise the equipment utilisation rate

- Reliable data helps to plan investments and improved cost control produce direct cost savings

- More effective maintenance management minimises equipment downtime

- Improved risk management results in fewer costly

- Purchase history, maintenance history, and renewal needs can be verified instantly

- Efficient workflow for inventories reduce the working time spent on annual inventories

- Removing unnecessary equipment allows to reduce storage and insurance costs

- Smaller carbon footprint due to fewer purchases and longer equipment life cycle

- The continuous ability to create detailed reports ensures the reliability of information and the correctness of decision-making

Summary

Adopting the culture of sustainable and effective equipment management as one of the company's core operations brings measurable savings. A modern company also prepares to meet the challenges brought by increasing inflation, component shortages, and the environmental crisis by making full use of its existing movable property and equipment.

Changing the culture always requires time, effort and active key persons, but with the right tools, the AssetOps culture quickly pays for itself.

Do you want to hear the ROI of equipment management in your company? Contact us!