What is equipment management – 10 principles of equipment life cycle management

8.8.2021

Equipment management is an ongoing process aimed at optimising the lifecycle of a company’s fixed assets. This article delves into the core elements of equipment management and how they can be applied across various organisations.

Equipment management isn't exclusive to specific industries or company sizes. A general rule of thumb is that if you struggle to list all your company’s fixed assets, completed maintenance tasks, or the date of equipment acquisition, it’s worth considering digital equipment management. The benefits of such an investment include cost savings and fostering a more responsible equipment management culture.

Table of Contents

Why is it important to manage the lifecycle of equipment?

Responsibility and sustainability

What tasks are involved in equipment management

Different methods of equipment management

What is the difference between equipment management and fixed asset accounting?

Implementing and using an equipment management system

Asset tracking and labelling

Inventory of fixed assets

Building culture

Equipment sharing and shared warehouses

Summary

1. Why is it important to manage the lifecycle of equipment?

Consider this scenario: it’s springtime, and you’ve just purchased a new bicycle. You enjoy riding it throughout the summer, but when winter comes, you leave it outside in the harsh Nordic weather. By the time you want to use it again, the bike's condition has deteriorated, and restoring it to its former glory comes at a cost.

On the other hand, if you had taken care of the bike from the beginning by storing it indoors during winter, it would have been in good condition for many summers to come. Prioritising equipment lifecycle management ensures that the productivity of your asset investment is maximised.

The same principle applies to any company or organisation’s equipment. When equipment use is supplemented with lifecycle management, the benefits include:

Optimised return on investment (ROI)

Reduced need for equipment replacement

Decreased equipment waste

Extended equipment lifespan

Controlled maintenance costs

Simplified insurance value management

The ability to operate sustainably in all equipment purchases

Beyond improving productivity, equipment lifecycle management also involves handling equipment after its useful life has ended. Could it be sold on the secondary market? How should it be recycled? These questions are at the heart of sustainability and resource-efficient operations, which are essential for enhancing the sustainability of any organisation.

2. Responsibility and sustainability

The degradation of the Earth's carrying capacity is increasingly placing demands on business operations. Companies must be able to integrate responsibility into their operations. Failing to do so is disastrous, as customers and financiers are increasingly demanding more responsible practices.

Smart equipment management helps companies incorporate sustainability into all their operations. As a result, companies pay attention to all their assets, machinery, and equipment. This ensures that companies know what they own, take care of their assets, and avoid unnecessary purchases.

"When companies know what they own, they can take care of the assets and avoid unnecessary purchases"

In this post, I will later emphasise how the core idea of lifecycle management is to maximise the lifespan of assets. By extending the life of the assets you own, you avoid unnecessary purchases, which conserves natural resources and reduces the company's carbon footprint.

Lifecycle management also improves the productivity of assets. Responsibility for assets is by no means a cost, but rather an investment that pays for itself quickly.

Download the whitepaper: Guide to Responsible Equipment Management

3. What task are involved in equipment management?

As mentioned earlier, the goal of equipment management is to optimise the lifecycle of your assets. But what does optimising the lifecycle of movable assets entail?

In practice, equipment management encompasses the following key areas:

Maintaining an up-to-date asset register and conducting inventories

Proactive maintenance planning, upkeep, and fault reporting

Planning for asset renewal and acquisitions

Managing asset usage and reservation functionalities

By ensuring that your company has processes in place for these areas, you’re well on your way to effective equipment management. A versatile equipment management system can streamline operations, making equipment management an integral part of your daily activities.

4. Different methods of equipment management

Proper equipment management is crucial. It provides confidence in knowing what equipment your organisation owns, how to optimise productivity, and supports taking greater responsibility for operations.

There are various ways to manage fixed assets. However, not all methods are suitable for every situation.

Here are the most common methods:

Employee memory

Pen & paper

Excel or similar spreadsheets

Maintenance management system

Equipment management system

ERP (Enterprise Resource Planning)

Yes, you guessed it – the first two methods are the most common. They’re perfectly acceptable options for a newly established company when there isn’t much to manage. A few laptops and a single van can easily be remembered.

However, as a company grows, it becomes clear that a system based on memory or paper is neither reliable nor secure. There’s a risk of people leaving and taking valuable equipment knowledge with them.

Spreadsheets

Spreadsheets are a more advanced solution compared to pen & paper. Skilled users can manage maintenance and reservations through spreadsheets, which can be a reasonable solution for small companies. However, spreadsheets are static and prone to conflicting duplicates. Their user interface is not very intuitive, which increases the risk of missed updates.

Maintenance systems

Maintenance systems are often used by companies where usability and condition tracking are important. These systems are designed to manage maintenance requests and plans efficiently. However, they lack other essential features of equipment management, such as inventories, investment planning, or equipment reservations.

Equipment management systems

An equipment management system is a digital tool for managing the lifecycle of equipment. In addition to maintenance features, it includes all the necessary functionalities to maximise equipment productivity. These features include an asset register, asset labelling, management of asset reservations and loans, inventory management, and asset investment planning.

A comprehensive equipment management system ensures that asset information is transparent and accessible to all who need it. We’ll discuss equipment management systems in more detail later in this article.

ERP systems

ERP systems are often used by more mature companies. ERPs typically include some asset management features, such as maintenance, reservations, and inventories. However, the downside of using an ERP for asset management is that these functionalities are often accessible to only a few people and can be complex to use. Additionally, ERP licence fees are substantial, and any changes to the service can be costly.

In many cases, an equipment management system is used alongside an ERP due to its superior usability. Equipment operations and lifecycle management can be managed more efficiently through an equipment management system. In these setups, it’s essential to ensure open API interfaces on both sides to enable seamless integration.

5. What is the difference between equipment management and fixed asset accounting?

The finance department usually has the best overall view of an organisation's fixed assets. However, this "best view" often comes with limitations. While other departments might only have rough estimates, finance at least has fixed asset accounting and reports to rely on. However, it's important to note that fixed asset accounting is not sufficient on its own, for several reasons.

Why isn't fixed asset accounting enough? The primary reason is that it's not timely enough to provide an accurate and reliable view of an organisation's fixed assets. Another key issue is that the information is not transparent - it's typically only available to finance personnel.

Fixed asset accounting usually answers questions about what has been purchased and which equipment still holds value on the balance sheet. However, this has little to do with the equipment that is actively used within the organisation.

Fixed asset accounting doesn't, for example, indicate which equipment has been lost or damaged. This information can only be obtained through an inventory, which is often time-consuming unless smart asset tags are used. Traditional inventories reveal only what assets are found, not what has been lost and why.

Moreover, many devices (such as AV equipment) have a technical lifespan that far exceeds their accounting depreciation period. If you rely solely on fixed asset accounting, this information is overlooked. It's far more prudent to plan future purchases based on the actual end-of-life of equipment rather than the depreciation schedule.

Fixed asset accounting is, of course, necessary and often required by law. However, on its own, it provides a narrow view of assets. Efficient equipment management processes help companies maximise the lifespan and productivity of their equipment.

Without delving too deeply into additional differences, here's a summary of the most significant distinctions between fixed asset accounting and equipment management:

Fixed asset accounting tracks what assets have been purchased and are being depreciated. Equipment management provides a comprehensive and timely view of all owned and operated equipment.

Fixed asset accounting information is only available to a limited number of people within the organisation. Equipment management information is accessible to all who need it and work with the assets.

Fixed asset accounting doesn't assist with managing maintenance, reservations, investments, or transfers between locations.

Fixed asset accounting usually includes financial thresholds for tracked assets (e.g., €2,000 or ¬€10,000), meaning less expensive assets may not be tracked at all. Equipment management covers all relevant equipment, whether through operational use or value.

Fixed asset accounting doesn't record information about lost equipment, nor the reasons or timing of its loss. An equipment management system can log all of this information.

6. Implementing and using an equipment management system

Managing equipment without a digital system is cumbersome. But how should you start with a digital equipment management tool? Here are the simplified steps for implementation:

Choosing an equipment management system

Appointing a responsible person and key users

Selecting labelling technology (RFID, NFC, QR code, or a combination)

Gathering information through an asset inventory

Labelling equipment

Continuous use of the equipment management system

The first step, of course, is choosing the right equipment management system. It’s advisable to list all your challenges, needs, and wishes to find the system that best suits you. Testing the software before making a decision is crucial, as it allows you to evaluate your internal processes and asset management culture.

When purchasing the system, it’s wise to appoint one or two superusers. Their responsibility will be to manage the equipment and serve as key users for the system. During implementation, it's recommended to also appoint a few key users in addition to the superusers. These key users will be responsible for implementing the processes in their respective departments.

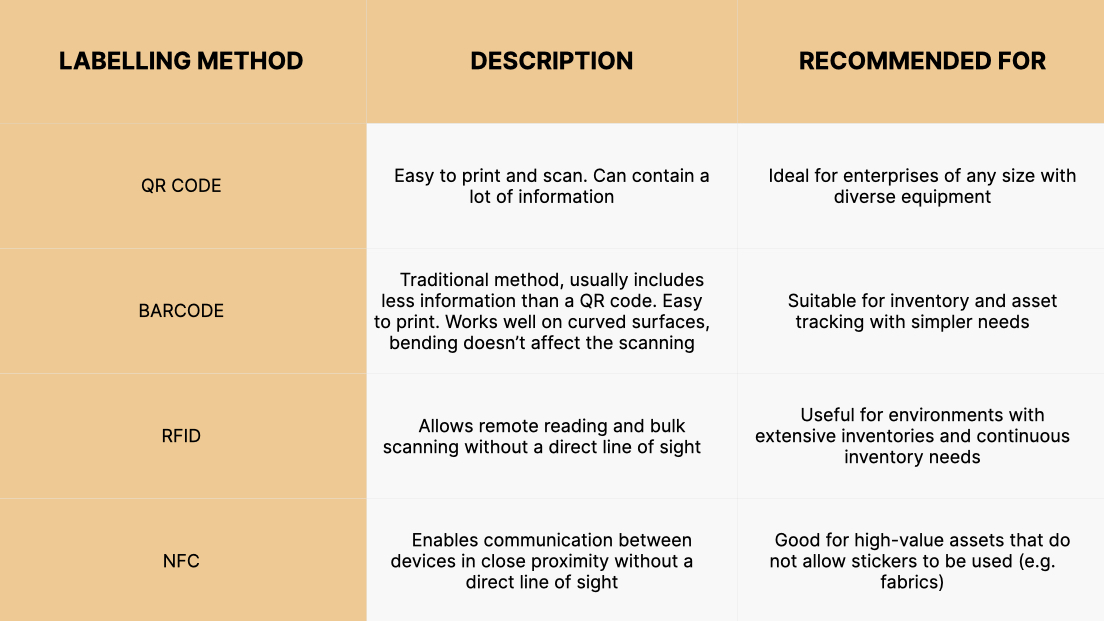

Before implementing the software, choose the best labelling technology and material. Common technologies include QR code, barcode, RFID, and NFC, or a combination of these. The practical difference between these technologies lies in how they are scanned.

It’s always possible to expand the use of different labels later as the system’s use expands. In the initial phase, carefully choose the first labelling method during implementation. We’ll explore the different labelling options in more detail later.

The initial inventory is the most time-consuming but also the most important part of the system implementation process. Once you’ve completed the initial inventory, you’ve taken a significant step forward in managing the entire lifecycle of your equipment. The initial inventory involves listing, labelling, and uploading all necessary equipment information into the equipment management system. When this is done, you can enjoy the benefits of efficient equipment management.

After the initial inventory, maintaining the equipment management system is easy. You’ll achieve success by ensuring that information is recorded at the time of the transaction, whether it’s a new acquisition, a move, or a maintenance task. This way, you’ll build a reliable database of your company’s equipment.

7. Asset tracking and labelling

In most cases, equipment should be labelled when taken into use. The labels help identify and track the equipment throughout its lifecycle. Today, the best labelling technologies are QR code, barcode, RFID, and NFC. While the last two are mainly used in combination with the first two, they offer advanced functionalities.

Labelling equipment is generally not mandatory, but it’s an easy way to ensure efficient asset tracking. Without labels, identifying similar equipment can become difficult over time. Moreover, without the correct label, your inventory may not be as reliable. Labels are also used to make equipment available for reservations and transfers.

An organisation should choose a labelling method that best suits its needs. Below is a comparison of the most commonly used methods:

For labelling to work effectively, you should consider the environment and use cases. For example, RFID may be the best choice in environments where equipment is frequently moved or large volumes are involved. In contrast, barcodes might be more suitable for simpler applications.

8. Inventory of fixed assets

In theory, an inventory of fixed assets is simple: the task is to compare what the company owns with what it should own. This sounds straightforward, but it requires resources and planning.

As a rule of thumb, the more effort you put into the first inventory, the easier it will be to conduct subsequent inventories. The first inventory serves as the foundation for the equipment management system, so thoroughness is key.

"The more effort you put into the first inventory, the easier it will be to conduct subsequent inventories"

The first step in conducting an inventory is planning. It’s helpful to think of it as a project. Questions to consider include:

Who will participate in the inventory?

When will the inventory take place?

How will the equipment be labelled?

How will the information be recorded?

After planning, start with the actual inventory. Divide the inventory into manageable sections, and assign responsibility to specific individuals for each area. This approach ensures that nothing is overlooked.

After completing the inventory, compare the recorded information with existing records. Identify any discrepancies and investigate them thoroughly. For example, if equipment is missing, it’s crucial to understand why and when it went missing.

With a solid inventory in place, you’ve taken a significant step forward in equipment management. It will make managing the lifecycle of your equipment much easier.

9. Building culture

Sustainable equipment management requires not only effective tools but also a strong culture. It's crucial to focus on building the right culture if you want to take your company's equipment management into the 2020s.

Changing culture is never easy. Key factors for success include committed key personnel, adequate resources, communication, motivation, and time.

Designated key personnel are responsible for creating and training other employees on the company's internal asset management processes. At the same time, they must ensure that new practices become established through their own example.

Naturally, this requires time and resources. Key personnel must therefore be guaranteed enough work time and authority to develop and implement these practices.

It's also important to motivate the staff to adapt to the new culture. Motivation can be aided, for example, by highlighting the cost savings and positive environmental impacts brought about by equipment management. Surely everyone is interested in the fact that budgets can be used more wisely as waste and unnecessary purchases decrease.

10. Equipment sharing and shared warehouses

Wise use of resources is emerging as a key sustainability trend. Why should geographically close partners own the same equipment when they could utilize each other's devices?

For example, companies and universities could share research equipment, or performing arts organisations could share sets and props. The lack of suitable systems has slowed this development.

The next major step in lifecycle management is equipment sharing and joint use. Through sharing, companies can utilize each other's equipment and thereby enhance resource-wise operations.

Reliable equipment sharing requires functional systems as support. Information on available equipment should be easily accessible, and booking it should be possible without unnecessary phone calls or emails.

An advanced equipment management system is essential for companies to share information about shared equipment with each other.

In equipment sharing, trust and control are key. It makes sense to start sharing, for example, with close partners, where equipment sharing is more controlled.

Summary

What is equipment management? It means better ability for you, your company, or your organisation to manage and optimize the lifecycle of your company's assets—from investment planning to disposal. By managing your equipment and incorporating lifecycle thinking into the maintenance of fixed assets, you improve the productivity of your equipment and operate more responsibly.

In the 2020s, a responsible company no longer acquires assets with a disposable mindset but ensures that equipment lasts long and is recyclable at the end of its lifecycle. In the future, the joint use of equipment between different organisations will also become more emphasized.

Asset management is not just about attaching labels to the company's devices and objects, but also includes the maintenance of equipment, management of bookings, investment planning, and inventories. Additionally, it involves a cultural shift within your company: asset management processes must be created, and responsible individuals appointed.

Lifecycle management saves resources. It means financial savings for your company and more efficient use of natural resources. It's a prime example of a win-win situation.