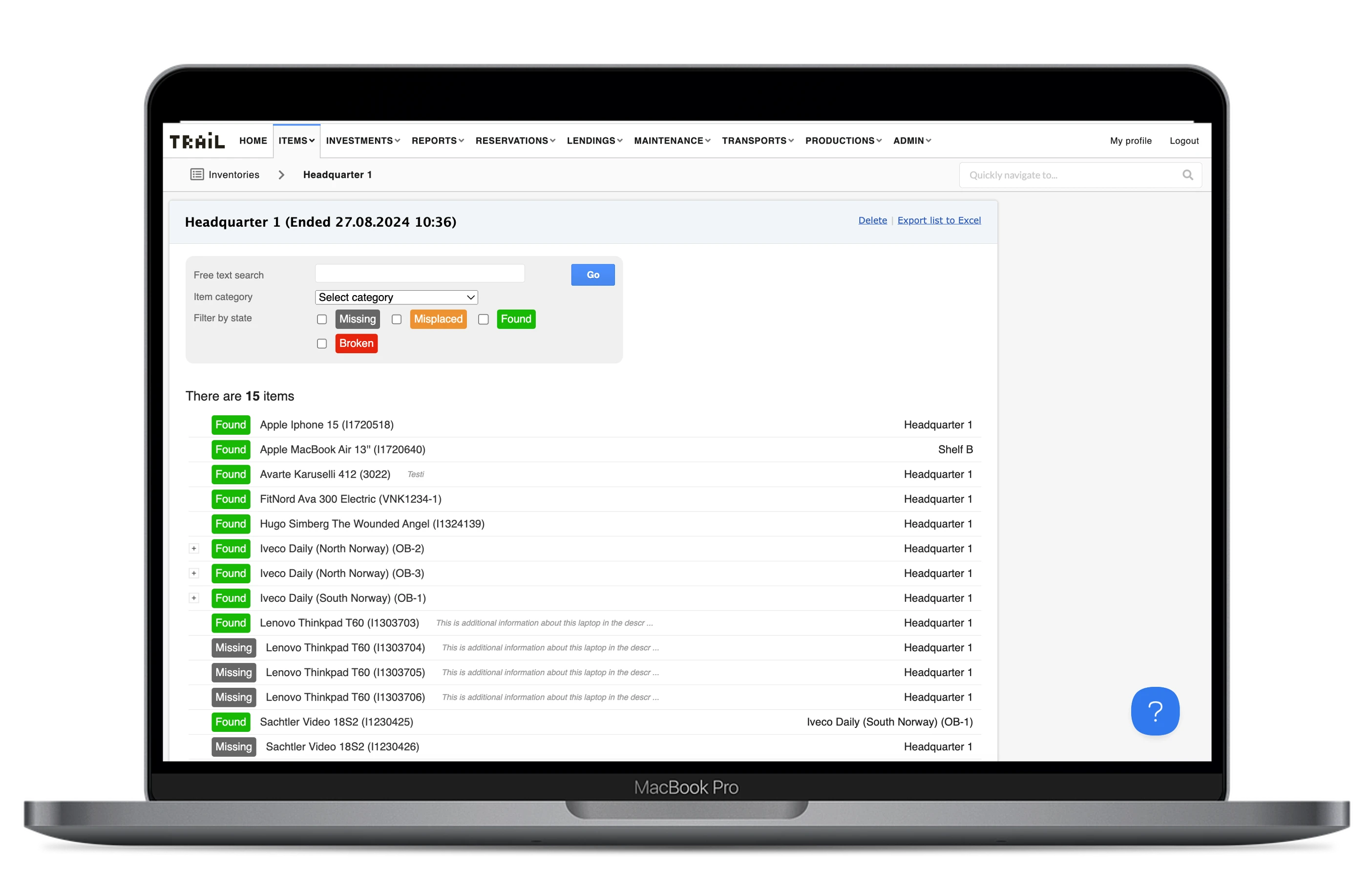

Reliable and timely inventory updates

With Trail, inventory tracking can be completed in just minutes, making the information instantly accessible to everyone who needs it. When it's time to verify the quantity and condition of items in a specific location, labelled assets and an efficient inventory process are crucial. In asset-intensive operations, inventory management is at the heart of the business, making reliable, timely, and easily accessible information essential.

Key benefits

Saved time by efficient inventory capability

Ability to produce inventory lists of equipment

Reliable and timely asset information

In Trail, the inventory list is generated based on labelled equipment. Each unique identifier is scanned during inventory, and the associated information is stored in Trail. This inventory list can be easily exported later for reporting or other purposes.

Labelling equipment offers significant advantages, including the accountability of information and the digital traceability of each item, capturing all actions performed. These benefits are accessible with any asset labelling technology.

RFID technology has revolutionised inventory tracking. RFID tags can be scanned from several meters away, allowing all equipment in a given space to be accounted for within seconds. In asset-intensive operations, the ability to complete inventory checks quickly and the time saved compared to traditional methods make a substantial impact.

Trail answers to the following questions:

What assets are currently in a given space?

Are there observations of missing assets during an inventory?

Are there misplaced assets?